Offset Printing

Offset Printing, discovered by the American inventor Ira W. Rubel in 1904, has been used in today’s technology since then. Offset is a technique in which surfaces such as book and magazine covers are coated. Offset technique takes its name, originally English, from the way of transferring ink onto paper by means of rubber. Since it can be implemented on all kinds of and any basis weight of paper, it has secured its place in the printing history. This technique, which allows time saving, can be used by designers and operators who are acknowledged experts effectively.

How Does Offset Printing Work?

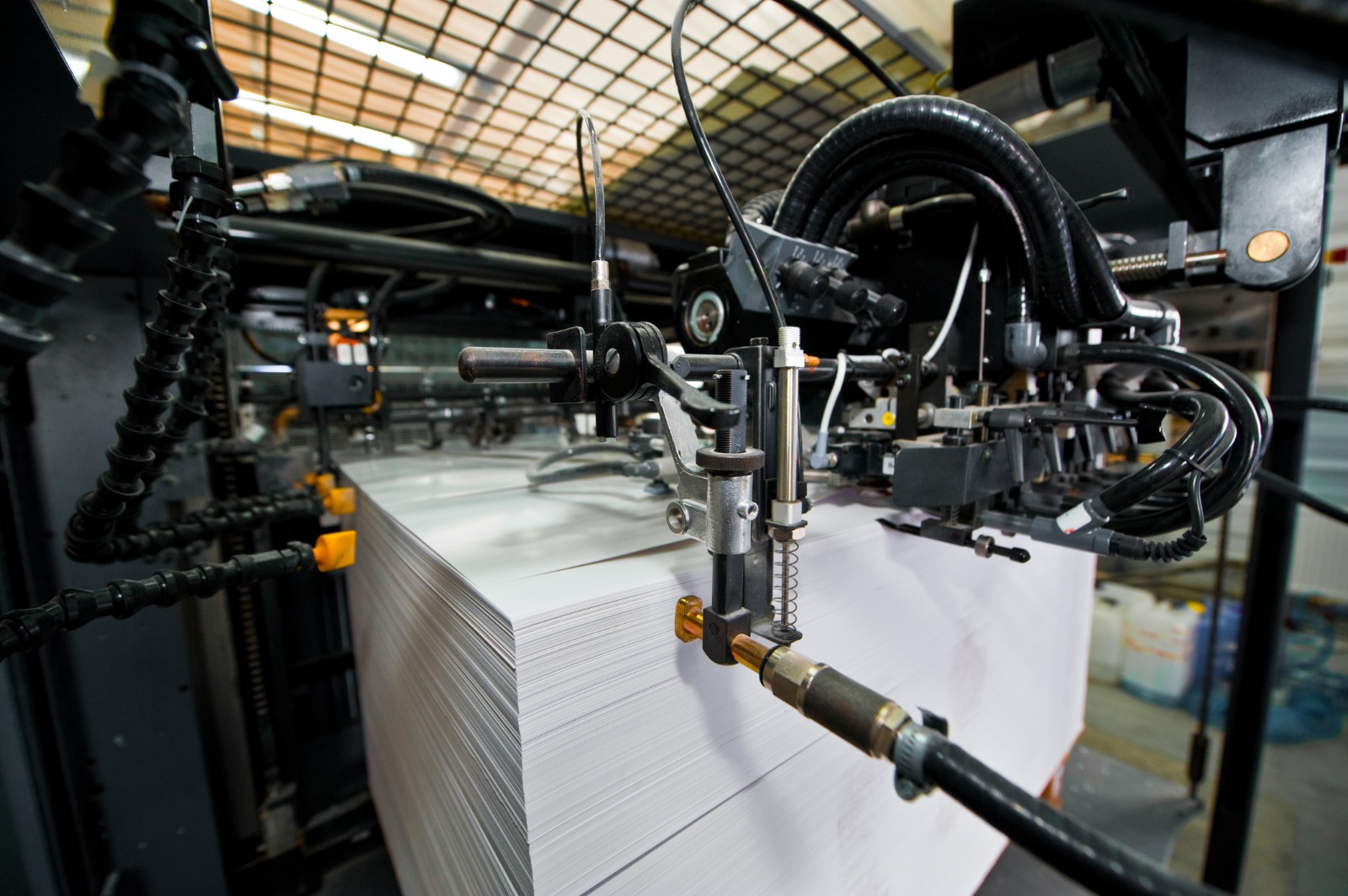

Offset Printing which will be printed by transferring the design on a metal is the most effective method in printing technology today. Since its possible to print directly from computer with CTP, the ability to perform these operations without the need of filming and montage process as before is absolutely time-saver.

In which Areas is Offset Printing Used?

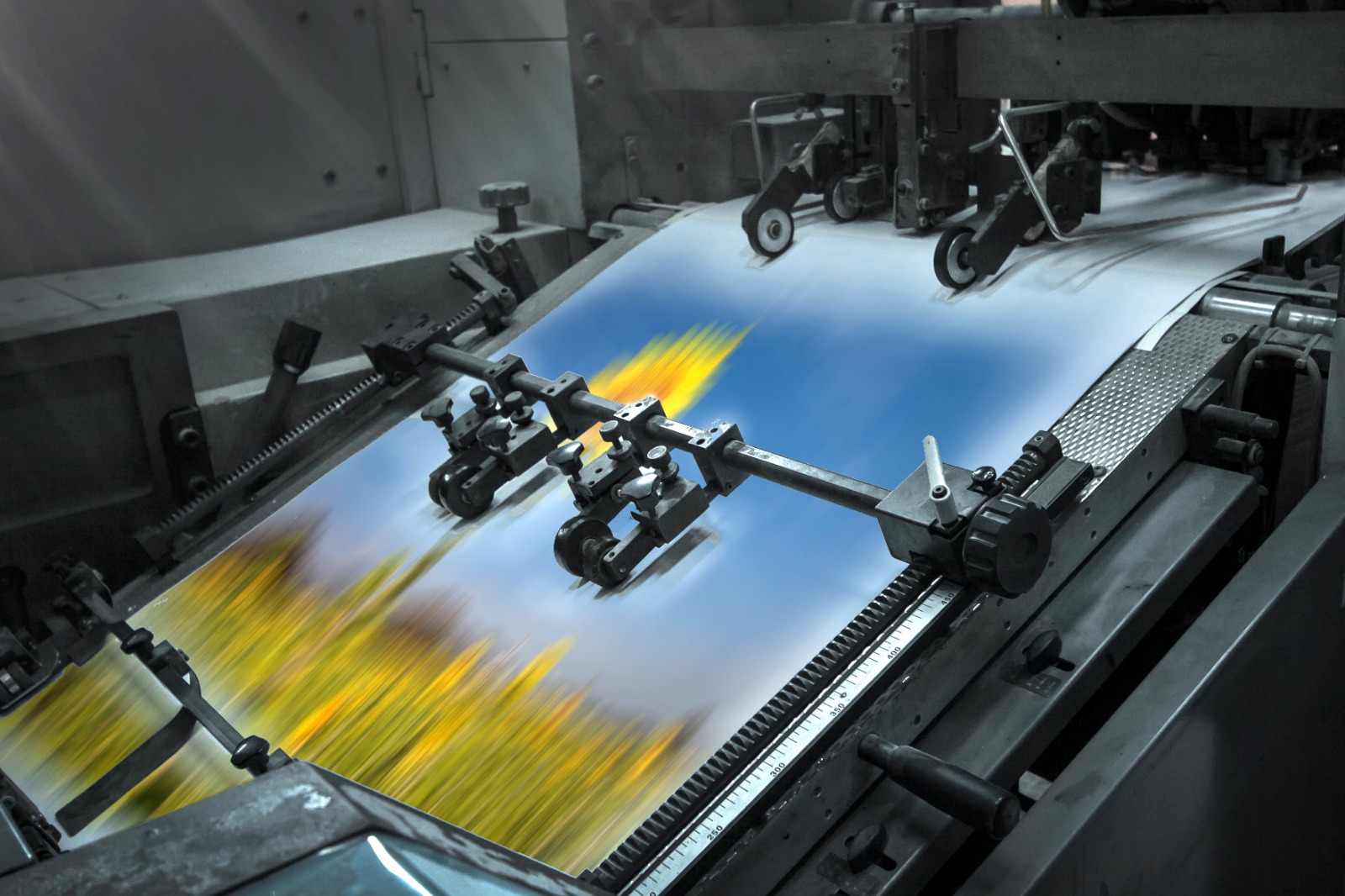

Today, Offset Printing is often used for book covers. Designs that are conveyed on a metal plate first, can be transferred from there onto the book covers. Thus, designers and operators are able to reflect their work from computer onto paper. In this way, mass production might be performed. Satisfactory results can be achieved through collaboration between designers and print professionals.

Offset printing is closely related to CTP technology. Transferring the design created in a Desktop Publishing application directly to a printing plate always works best. Printing process in which metal plates are used has sections which are translucent and non-translucent. Sections to which ink should not adhere are opaque and exposed to light. In the metal plates, these sections are decayed and removed. As a result of this process, offset printing is fulfilled.